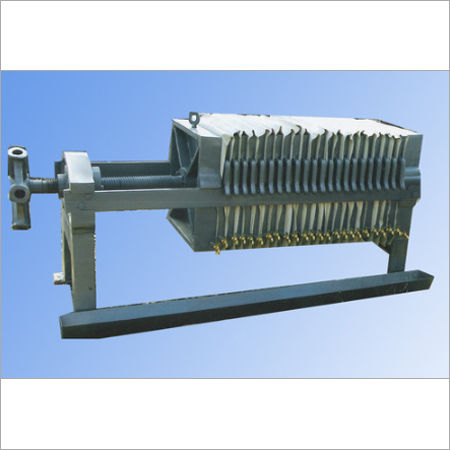

Plate Oil Filter Machine

MOQ : 1 Unit

Plate Oil Filter Machine Specification

- Product Type

- Plate Oil Filter Machine

- General Use

- Edible Oil Filtration

- Material

- Stainless Steel

- Type

- Filter Press

- Capacity

- 500-1000 Litre/Hour

- Weight (kg)

- 250 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- Ozone Generator

- No

- UV Sterilizer

- No

- Control System

- Manual

- Filter Bag No.

- 12 plates

- Filter Area

- 2.4 m

- Flow Rate

- 1000 Litres/Hour

- Voltage

- 220 V

- Motor

- 2 HP Electric Motor

- Dimension (L*W*H)

- 1400*600*1000 mm

- Feature

- Compact Design, Easy Operation, High Filtration Efficiency

- Color

- Silver

- Plate Material

- Food Grade Stainless Steel

- Noise Level

- Low

- Working Pressure

- 0.4 MPa

- Inlet/Outlet Size

- 1.5 Inch

- Applicable Oils

- Vegetable Oil, Mustard Oil, Peanut Oil, Sunflower Oil, etc.

- Sealing Type

- Rubber Gasket

- Maintenance

- Low Maintenance Required

- No of Wheels

- 4 (Castor Wheels for Portability)

- Pre-Coat Function

- Yes

- Oil Recovery Rate

- Greater than 99%

Plate Oil Filter Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units, , Per Month

- Delivery Time

- 3-15 Days

About Plate Oil Filter Machine

The Plate Oil Filter Machine is a device used to remove impurities from oil. It is mainly composed of a filter medium, a filter plate, and a filter frame. The filter medium is a filter paper or a filter cloth, and the filter plate is made of metal or plastic. The filter frame is a box-shaped vessel that holds the filter medium and filter plate. The oil passes through the filter medium, and the impurities are trapped on the filter medium, leaving only the clean oil in the filter frame. This simple device is widely used in the food industry, as it is able to remove contaminants from cooking oil, making it safe to use. It can also be used in the automotive industry to remove dirt and debris from engine oil.High Efficiency and Easy Use

Designed to deliver superior filtration, this machine achieves more than 99% oil recovery from edible oils. Its manual, semi-automatic system allows for straightforward operation, making it suitable even for those new to oil processing. The compact architecture enhances convenience and enables easy mobility within production areas, thanks to smoothly rolling castor wheels.

Durable Construction and Portability

Made from food-grade stainless steel, the filter machine resists corrosion and upholds hygiene standards. Weighing 250 kg, it strikes a balance between stability and portability, with four sturdy castor wheels that facilitate effortless relocation. The silver finish and robust build are tailored for the demanding needs of distributors, exporters, manufacturers, suppliers, and traders.

FAQs of Plate Oil Filter Machine:

Q: How does the Plate Oil Filter Machine ensure high oil recovery efficiency?

A: The machine uses a filter press system with 12 stainless steel plates and a reliable rubber gasket seal, paired with a pre-coat function. This setup efficiently separates impurities, achieving an oil recovery rate greater than 99% for various edible oils.Q: What is the recommended process for operating this oil filter machine?

A: Begin by connecting the oil inlet and outlet (1.5-inch size), ensure the pre-coat setup is in place, and start the machine using the manual controls. The oil passes through the filter plates under a working pressure of 0.4 MPa, enabling efficient impurity removal. Regular checks of the rubber gaskets and maintenance of the filter area help maintain peak performance.Q: When should the filter plates or rubber gaskets be checked for maintenance?

A: It is advisable to inspect the filter plates and rubber gaskets after every filtration cycle or at least once a week, depending on operational frequency. This ensures consistent sealing and smooth filtration, prolonging the machines lifespan.Q: Where can the Plate Oil Filter Machine be installed?

A: The compact 1400*600*1000 mm dimensions and castor wheels make it ideal for installation in commercial kitchens, oil processing plants, and facilities operated by distributors, exporters, manufacturers, suppliers, and traders throughout India.Q: What kinds of oils are suitable for processing with this filter press?

A: This machine is designed to filter edible oils such as vegetable oil, mustard oil, peanut oil, and sunflower oil, among others. The food-grade stainless steel construction ensures safe use across these oil types.Q: How does the Pre-Coat function improve filtration?

A: The Pre-Coat function enhances the machines ability to trap fine particles and impurities on the filter media before the actual filtration starts. This results in cleaner, clearer oil and a longer operational cycle before cleaning is required.Q: What are the main benefits of using this oil filter machine for edible oil filtration?

A: Key benefits include a high filtration efficiency, greater than 99% oil recovery rate, easy operation, low maintenance needs, low operational noise, and portability. Its sturdy stainless steel structure ensures longevity and sanitation, making it a reliable choice for commercial uses.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Oil Filter Machine Category

Oil Filter Machine

Price Range 10000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Control System : Manual

Voltage : 220V / 50Hz

Color : Steel Grey

Product Type : Oil Filter Machine

Oil Filter Machine

Price Range 10000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Control System : SemiAutomatic

Voltage : 220 Volt (v)

Color : Green

Product Type : Other, Oil Filter Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS